35sh Magnetic of Pneumatic Component Material

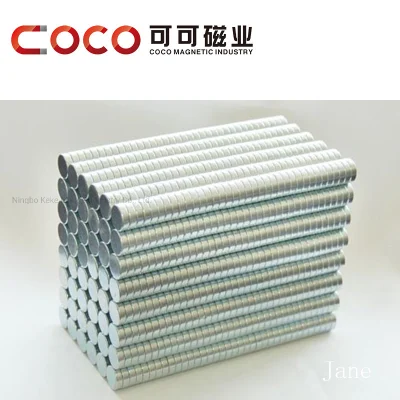

Product Name: 35SH magnetic of pneumatic component material Materials Trademark: The products of 35SH series, coated wit

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | YCX |

| Composition | NdFeB Magnet |

| Transport Package | According to Your Request |

| Specification | RoHs |

| Trademark | COCO |

| Origin | Zhejiang Ningbo China |

| Production Capacity | 2000t/Y |

Product Description

Product Name: 35SH magnetic of pneumatic component materialMaterials Trademark:

The products of 35SH series, coated with Nickel. Suitable for all kinds of Pneumatic Components. A high performance magnetic product by my company.

Magnets grade: 35sh

Magnets size: As the drawing

Magnetism direction: Which direction to oriented The north pole and south pole

Magnets coating: Zn,

Quantities: More mass order quantities. More Lower the prices.

Original factory.

If you haven't been able to find your desired size or strength in our website?

We can send you a price quotation for exactly the magnet you wish.

Tell us which features you desire in a magnet and the quantity you will require.

You will receive our price quotation via e-mail within a day.

When inquiring or ordering, please send us following information

1. Type of magnet (material & grade)

2. Quantity (annual and per shipment)

3. Shape and dimensions (drawing if necessary)

4. Direction of magnetization

5. Magnetized or unmagnetized

6. Details of surface treatment

7. Application if possible

8. Other information and/or requirements

We hope to cooperate with you. Thank you.

| Magnetic properties of Sintered Neodymium Magnet (NdFeB magnet): | |||||

| Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Max. Operating Temperature |

| Br mT (kGs) | Hcb kA/m (kOe) | Hcj kA/m (kOe) | ( BH )max kJ/m 3 (MGOe) | Tw | |

| N35 | 1170-1220 (11.7-12.2) | ≥ 868 ( ≥ 10.9) | ≥ 955 ( ≥ 12) | 263-287 (33-36) | 80 deg |

| N38 | 1220-1250 (12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 955 ( ≥ 12) | 287-310 (36-39) | 80 deg |

| N40 | 1250-1280 (12.5-12.8) | ≥ 907 ( ≥ 11.4) | ≥ 955 ( ≥ 12) | 302-326 (38-41) | 80 deg |

| N42 | 1280-1320 (12.8-13.2) | ≥ 915 ( ≥ 11.5) | ≥ 955 ( ≥ 12) | 318-342 (40-43) | 80 deg |

| N45 | 1320-1380 (13.2-13.8) | ≥ 923 ( ≥ 11.6) | ≥ 955 ( ≥ 12) | 342-366 (43-46) | 80 deg |

| N48 | 1380-1420 (13.8-14.2) | ≥ 923 ( ≥ 11.6) | ≥ 876 ( ≥ 12) | 366-390 (46-49) | 80 deg |

| N50 | 1400-1450 (14.0-14.5) | ≥ 796 ( ≥ 10.0) | ≥ 876 ( ≥ 11) | 382-406 (48-51) | 60 deg |

| N52 | 1430-1480 (14.3-14.8) | ≥ 796 ( ≥ 10.0) | ≥ 876 ( ≥ 11) | 398-422 (50-53) | 60 deg |

| 30M | 1080-1130 (10.8-11.3) | ≥ 796 ( ≥ 10.0) | ≥ 1114 ( ≥ 14) | 223-247 (28-31) | 100 deg |

| 33M | 1130-1170 (11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 1114 ( ≥ 14) | 247-263 (31-33) | 100 deg |

| 35M | 1170-1220 (11.7-12.2) | ≥ 868 ( ≥ 10.9) | ≥ 1114 ( ≥ 14) | 263-287 (33-36) | 100 deg |

| 38M | 1220-1250 (12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 1114 ( ≥ 14) | 287-310 (36-39) | 100 deg |

| 40M | 1250-1280 (12.5-12.8) | ≥ 923 ( ≥ 11.6) | ≥ 1114 ( ≥ 14) | 302-326 (38-41) | 100 deg |

| 42M | 1280-1320 (12.8-13.2) | ≥ 955 ( ≥ 12.0) | ≥ 1114 ( ≥ 14) | 318-342 (40-43) | 100 deg |

| 45M | 1320-1380 (13.2-13.8) | ≥ 995 ( ≥ 12.5) | ≥ 1114 ( ≥ 14) | 342-366 (43-46) | 100 deg |

| 48M | 1360-1430 (13.6-14.3) | ≥ 1027 ( ≥ 12.9) | ≥ 1114 ( ≥ 14) | 366-390 (46-49) | 100 deg |

| 50M | 1400-1450 (14.0-14.5) | ≥ 1033 ( ≥ 13.0) | ≥ 1114 ( ≥ 14) | 382-406 (48-51) | 100 deg |

| 30H | 1080-1130 (10.8-11.3) | ≥ 796 ( ≥ 10.0) | ≥ 1353 ( ≥ 17) | 223-247 (28-31) | 120 deg |

| 33H | 1130-1170 (11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 1353 ( ≥ 17) | 247-271 (31-34) | 120 deg |

| 35H | 1170-1220 (11.7-12.2) | ≥ 868 ( ≥ 10.9) | ≥ 1353 ( ≥ 17) | 263-287 (33-36) | 120 deg |

| 38H | 1220-1250 (12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 1353 ( ≥ 17) | 287-310 (36-39) | 120 deg |

| 40H | 1250-1280 (12.5-12.8) | ≥ 923 ( ≥ 11.6) | ≥ 1353 ( ≥ 17) | 302-326 (38-41) | 120 deg |

| 42H | 1280-1320 (12.8-13.2) | ≥ 955 ( ≥ 12.0) | ≥ 1353 ( ≥ 17) | 318-342 (40-43) | 120 deg |

| 45H | 1300-1360 (13-13.6) | ≥ 963 ( ≥ 12.1) | ≥ 1353 ( ≥ 17) | 326-358 (43-46) | 120 deg |

| 48H | 1370-1430 (13.7-14.3) | ≥ 995 ( ≥ 12.5) | ≥ 1353 ( ≥ 17) | 366-390 (46-49) | 120 deg |

| 30SH | 1080-1130 (10.8-11.3) | ≥ 804 ( ≥ 10.1) | ≥ 1592 ( ≥ 20) | 223-247 (28-31) | 150 deg |

| 33SH | 1130-1170 (11.3-11.7) | ≥ 844 ( ≥ 10.6) | ≥ 1592 ( ≥ 20) | 247-271 (31-34) | 150 deg |

| 35SH | 1170-1220 (11.7-12.2) | ≥ 876 ( ≥ 11.0) | ≥ 1592 ( ≥ 20) | 263-287 (33-36) | 150 deg |

| 38SH | 1220-1250 (12.2-12.5) | ≥ 907 ( ≥ 11.4) | ≥ 1592 ( ≥ 20) | 287-310 (36-39) | 150 deg |

| 40SH | 1240-1280 (12.5-12.8) | ≥ 939 ( ≥ 11.8) | ≥ 1592 ( ≥ 20) | 302-326 (38-41) | 150 deg |

| 42SH | 1280-1320 (12.8-13.2) | ≥ 987 ( ≥ 12.4) | ≥ 1592 ( ≥ 20) | 318-342 (40-43) | 150 deg |

| 45SH | 1320-1380 (13.2-13.8) | ≥ 1003 ( ≥ 12.6) | ≥ 1592 ( ≥ 20) | 342-366 (43-46) | 150 deg |

| 28UH | 1020-1080 (10.2-10.8) | ≥ 764 ( ≥ 9.6) | ≥ 1990 ( ≥ 25) | 207-231 (26-29) | 180 deg |

| 30UH | 1080-1130 (10.8-11.3) | ≥ 812 ( ≥ 10.2) | ≥ 1990 ( ≥ 25) | 223-247 (28-31) | 180 deg |

| 33UH | 1130-1170 (11.3-11.7) | ≥ 852 ( ≥ 10.7) | ≥ 1990 ( ≥ 25) | 247-271 (31-34) | 180 deg |

| 35UH | 1180-1220 (11.8-12.2) | ≥ 860 ( ≥ 10.8) | ≥ 1990 ( ≥ 25) | 263-287 (33-36) | 180 deg |

| 38UH | 1220-1250 (12.2-12.5) | ≥ 876 ( ≥ 11.0) | ≥ 1990 ( ≥ 25) | 287-310 (36-39) | 180 deg |

| 40UH | 1240-1280 (12.5-12.8) | ≥ 899 ( ≥ 11.3) | ≥ 1990 ( ≥ 25) | 302-326 (38-41) | 180 deg |

| 28EH | 1040-1090 (10.4-10.9) | ≥ 780 ( ≥ 9.8) | ≥ 2388 ( ≥ 30) | 207-231 (26-29) | 200 deg |

| 30EH | 1080-1130 (10.8-11.3) | ≥ 812 ( ≥ 10.2) | ≥ 2388 ( ≥ 30) | 223-247 (28-31) | 200 deg |

| 33EH | 1130-1170 (11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 2388 ( ≥ 30) | 247-271 (31-34) | 200 deg |

| 35EH | 1170-1220 (11.7-12.2) | ≥ 876 ( ≥ 11.0) | ≥ 2388 ( ≥ 30) | 263-287 (33-36) | 200 deg |

| 38EH | 1220-1250 (12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 2388 ( ≥ 30) | 287-310 (36-39) | 200 deg |

| 30AH | 1080-1120 (10.8-11.2) | ≥ 812 ( ≥ 10.2) | ≥ 2785 ( ≥ 35) | 223-255 (28-32) | 220 deg |

| 33AH | 1120-1170 (11.2-11.7) | ≥ 812 ( ≥ 10.2) | ≥ 2785 ( ≥ 35) | 247-271 (31-34) | 220 deg |

| Physical and Mechanical Properties of Neodymium Magnet: | |||||

| Thermal Conductivity | 7.7 kcal/m-h-° C | ||||

| Young' s Modulus | 1.7 x 104 kg/mm2 | ||||

| Bending Strength | 24 kg/mm2 | ||||

| Compressive Strength | 80 kg/mm2 | ||||

| Electrical Resistivity | 160 µ -ohm-cm/cm2 | ||||

| Density | 7.4-7.55 g/cm3 | ||||

| Vickers Hardness | 500 - 600 | ||||

| Available coatings for sintered Neodymium Magnet (NdFeB magnet): | |||||

| Available Coatings: | |||||

| Surface | Coating | Thickness (Microns) | Color | Resistance | |

| Passivation | 1 | Silver Grey | Temporary Protection | ||

| Nickel | Ni+Ni | 10.0-20 | Bright Silver | Excellent against Humidity | |

| Ni+Cu+Ni | |||||

| Zinc | Zn | 8.0-20 | Bright Blue | Good Against Salt Spray | |

| C-Zn | Shinny Color | Excellent Against Salt Spray | |||

| Tin | Ni+Cu+Sn | 15-20 | Silver | Superior Against Humidity | |

| Gold | Ni+Cu+Au | 10.0-20 | Gold | Superior Against Humidity | |

| Copper | Ni+Cu | 10.0-20 | Gold | Temporary Protection | |

| Epoxy | Epoxy | 15-25 | Black, Red, Grey | Excellent Against Humidity & Salt Spray | |

| Ni+Cu+Epoxy | |||||

| Zn+Epoxy | |||||

| Chemical | Ni | 10.0-20 | Silver Grey | Excellent Against Humidity | |

| Parylene | Parylene | 5.0-20 | Grey | Excellent Against Humidity, Salt Spray. Superior Against Solvents, Gases, Fungi and Bacteria. FDA Approved. | |

Related Products

-

![Strong NdFeB Magnetic Rod with PTFE Coating]()

Strong NdFeB Magnetic Rod with PTFE Coating

-

![China Neodymium Magnet Blocks Magnet Big Block Magnets Magnetic Materials]()

China Neodymium Magnet Blocks Magnet Big Block Magnets Magnetic Materials

-

![Tedamag Factory High Quality Color Painted Educational Magnet Bar Industrial Magnet Round Guitar Pick up AlNiCo Permanent Magnet]()

Tedamag Factory High Quality Color Painted Educational Magnet Bar Industrial Magnet Round Guitar Pick up AlNiCo Permanent Magnet

-

![Magnetic Liquid Traps with PTFE Coating for Raw Material of Lithium Battery Product Line]()

Magnetic Liquid Traps with PTFE Coating for Raw Material of Lithium Battery Product Line