Rare Earth Magnets Grill NdFeB Round Magnetic Filter

Rare Earth Magnets Grill NdFeB Round Magnetic Filter Our CompanyNanjing Huajin Magnetic Materials Co., Ltd. Specializing

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | HJ-12000GS |

| Gauss | 6000-13000GS |

| Working Temp. | Max 176f/ 176f~392f |

| Density | 7.50-7.65g/cm3 |

| Lead Time | 7-9 Days |

| Payment Term | T/T, L/C, Paypal, Western Union |

| Trade Term | EXW, Fob, F&C, Fcr, CIF |

| Transport Package | Carton or Wooden Box |

| Specification | Customized |

| Trademark | HJ |

| Origin | Nanjing, Jiangsu, China |

| HS Code | 85051110 |

| Production Capacity | 500000set/Year |

Product Description

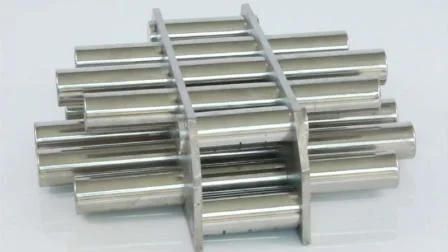

Rare Earth Magnets Grill NdFeB Round Magnetic Filter| Item | Magnetic Filter/grill/frame |

| Gauss | 6000-13000 Gauss |

| Material | Neodymium Magnet+SUS304/316L Pipe |

| Shape | Round, rectangle, single-level, double-level ect. |

| Working Temp. | Max 176F/ 176F~392F |

| Casing | SUS304/316L |

| Dimension | Customized |

| Application | Hopper, Industrial filter, food industry, Ceramic industry ect. |

| Performance | Permanent, Strong, Rust-proof, Anti-corrosion |

| Trade Term | EXW, FOB, CNF, CIF ect. |

| Payment Term | TT, PayPal, Western Union ect |

Our CompanyNanjing Huajin Magnetic Materials Specializing in the production and sale of magneticNdFeB, magnetic bar, magnetic products, magnetic frame. Magnets of various shapes and sizescan be produced according to customer requirements, such as packaging diskette, the motormagnetic tile, magnetic ring, toy bar magnet, magnetic ball, with the exception of iron magnetic rods,magnetic hooks, magnetic separator box; Surface treatment: Gold, silver, plated epoxy, nickel-platedcopper-nickel, zinc, chromium, titanium (blue zinc, black zinc, color zinc), above the surfacetreatment to meet environmental requirements.

| Grade | Remanence | Coercivity Force | Intrinsic Coercive Force | Max. Energy Product | Working Temp. | ||||

| Br | Hcb | Hcj | (BH)max | ||||||

| mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥ 868 | ≥ 10.9 | ≥ 955 | ≥ 12 | 263-287 | 33-36 | 80 ° C |

| N38 | 1220-1250 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 955 | ≥ 12 | 287-310 | 36-39 | 80 ° C |

| N40 | 1250-1280 | 12.5-12.8 | ≥ 907 | ≥ 11.4 | ≥ 955 | ≥ 12 | 302-326 | 38-41 | 80 ° C |

| N42 | 1280-1320 | 12.8-13.2 | ≥ 915 | ≥ 11.5 | ≥ 955 | ≥ 12 | 318-342 | 40-43 | 80 ° C |

| N45 | 1320-1380 | 13.2-13.8 | ≥ 923 | ≥ 11.6 | ≥ 955 | ≥ 12 | 342-366 | 43-46 | 80 ° C |

| N48 | 1380-1420 | 13.8-14.2 | ≥ 923 | ≥ 11.6 | ≥ 876 | ≥ 12 | 366-390 | 46-49 | 80 ° C |

| N50 | 1400-1450 | 14.0-14.5 | ≥ 796 | ≥ 10.0 | ≥ 876 | ≥ 11 | 382-406 | 48-51 | 60 ° C |

| N52 | 1430-1480 | 14.3-14.8 | ≥ 796 | ≥ 10.0 | ≥ 876 | ≥ 11 | 398-422 | 50-53 | 60 ° C |

| 35M | 1170-1220 | 11.7-12.2 | ≥ 868 | ≥ 10.9 | ≥ 1114 | ≥ 14 | 263-287 | 33-36 | 100 ° C |

| 38M | 1220-1250 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 1114 | ≥ 14 | 287-310 | 36-39 | 100 ° C |

| 40M | 1250-1280 | 12.5-12.8 | ≥ 923 | ≥ 11.6 | ≥ 1114 | ≥ 14 | 302-326 | 38-41 | 100 ° C |

| 42M | 1280-1320 | 12.8-13.2 | ≥ 955 | ≥ 12.0 | ≥ 1114 | ≥ 14 | 318-342 | 40-43 | 100 ° C |

| 45M | 1320-1380 | 13.2-13.8 | ≥ 995 | ≥ 12.5 | ≥ 1114 | ≥ 14 | 342-366 | 43-46 | 100 ° C |

| 48M | 1360-1430 | 13.6-14.3 | ≥ 1027 | ≥ 12.9 | ≥ 1114 | ≥ 14 | 366-390 | 46-49 | 100 ° C |

| 50M | 1400-1450 | 14.0-14.5 | ≥ 1033 | ≥ 13.0 | ≥ 1114 | ≥ 14 | 382-406 | 48-51 | 100 ° C |

| 35H | 1170-1220 | 11.7-12.2 | ≥ 868 | ≥ 10.9 | ≥ 1353 | ≥ 17 | 263-287 | 33-36 | 120 ° C |

| 38H | 1220-1250 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 1353 | ≥ 17 | 287-310 | 36-39 | 120 ° C |

| 40H | 1250-1280 | 12.5-12.8 | ≥ 923 | ≥ 11.6 | ≥ 1353 | ≥ 17 | 302-326 | 38-41 | 120 ° C |

| 42H | 1280-1320 | 12.8-13.2 | ≥ 955 | ≥ 12.0 | ≥ 1353 | ≥ 17 | 318-342 | 40-43 | 120 ° C |

| 45H | 1300-1360 | 13-13.6 | ≥ 963 | ≥ 12.1 | ≥ 1353 | ≥ 17 | 326-358 | 43-46 | 120 ° C |

| 48H | 1370-1430 | 13.7-14.3 | ≥ 995 | ≥ 12.5 | ≥ 1353 | ≥ 17 | 366-390 | 46-49 | 120 ° C |

| 33SH | 1130-1170 | 11.3-11.7 | ≥ 844 | ≥ 10.6 | ≥ 1592 | ≥ 20 | 247-271 | 31-34 | 150 ° C |

| 35SH | 1170-1220 | 11.7-12.2 | ≥ 876 | ≥ 11.0 | ≥ 1592 | ≥ 20 | 263-287 | 33-36 | 150 ° C |

| 38SH | 1220-1250 | 12.2-12.5 | ≥ 907 | ≥ 11.4 | ≥ 1592 | ≥ 20 | 287-310 | 36-39 | 150 ° C |

| 40SH | 1240-1280 | 12.5-12.8 | ≥ 939 | ≥ 11.8 | ≥ 1592 | ≥ 20 | 302-326 | 38-41 | 150 ° C |

| 42SH | 1280-1320 | 12.8-13.2 | ≥ 987 | ≥ 12.4 | ≥ 1592 | ≥ 20 | 318-342 | 40-43 | 150 ° C |

| 45SH | 1320-1380 | 13.2-13.8 | ≥ 1003 | ≥ 12.6 | ≥ 1592 | ≥ 20 | 342-366 | 43-46 | 150 ° C |

| 30UH | 1080-1130 | 10.8-11.3 | ≥ 812 | ≥ 10.2 | ≥ 1990 | ≥ 25 | 223-247 | 28-31 | 180 ° C |

| 33UH | 1130-1170 | 11.3-11.7 | ≥ 852 | ≥ 10.7 | ≥ 1990 | ≥ 25 | 247-271 | 31-34 | 180 ° C |

| 35UH | 1180-1220 | 11.8-12.2 | ≥ 860 | ≥ 10.8 | ≥ 1990 | ≥ 25 | 263-287 | 33-36 | 180 ° C |

| 38UH | 1220-1250 | 12.2-12.5 | ≥ 876 | ≥ 11.0 | ≥ 1990 | ≥ 25 | 287-310 | 36-39 | 180 ° C |

| 40UH | 1240-1280 | 12.5-12.8 | ≥ 899 | ≥ 11.3 | ≥ 1990 | ≥ 25 | 302-326 | 38-41 | 180 ° C |

Remarks:(1)."√"means it can be manufactured on the condition of the diameters listed in the table"- "means can not be manufactured. (2). The related Max working temperature from different series. H series: <=120 SH series: <=150 UH series: <=180 EH series: <=250 (3).Round and square are both available (4). 304 and 316L stainless steel type are available (5). Magnetic bar length can be customized .Max length is 2500mm when dia is 25mm. (6). Various end design are available ,such as Nail head ,thread hole ,double screw bolt.

Our advantage:

1. More than 10-year magnet manufacturing experience, quality, lead time, price andservice have been gauranteed.

2. Professional R&D department, with a professional technologist team.

3. Much Experienced Export Customs Declare Team.

4. Low MOQ and free samples.

Payment Term:T/T, L/C, Western Union, PayPal.Package & Shipment:1. By Express(DHL, FedEx, TNT, UPS ect): Door to door, Short Delivery time, 3-5 days.2. By Air: Short Delivery Time, 3-7 days.3. By Sea: Cheap Shipping Cost, 7-30 days.Package: Magnetic Isolation PackageCarton: 36*27*15CMHow to contact us?FAQ:1. How to get quick quotation?Kindly offer us the specific size, quantity, coating(zinc/nickel), magnetism direction ect otherrequiries. Then best price will be offered ASAP. 2.What about the lead time?(1) Sample: 5-7 days. (2) Batch quantity: 7-12 days.3.What's the MOQ?Normally regular Size: ≥1 Piece.4. Terms of Paymemt:(1). T/T in advance(telegraphic transfer-bank order)(2). Western Union cash - for small order or samples order.(3). PayPal- for small order, quick receiptPlease feel free to contact me for any questions and requiries.

Related Products