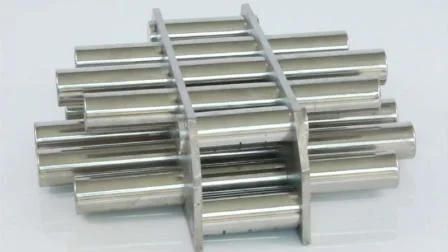

Liquid Magnet Quadrate-Trap Neodymium Magnet Magnetic Drawer Type Quadrate-Trap Liquid Magnetic

Ejet Trap Magnets are manufactured to remove micron sized ferrous metals from different kinds of liquids and slurry line

Send your inquiryDESCRIPTION

Basic Info

| Trademark | JSYY |

| Origin | Fushun, Liaoning, China |

| HS Code | 85051190 |

| Production Capacity | 1000 PCS/Year |

Product Description

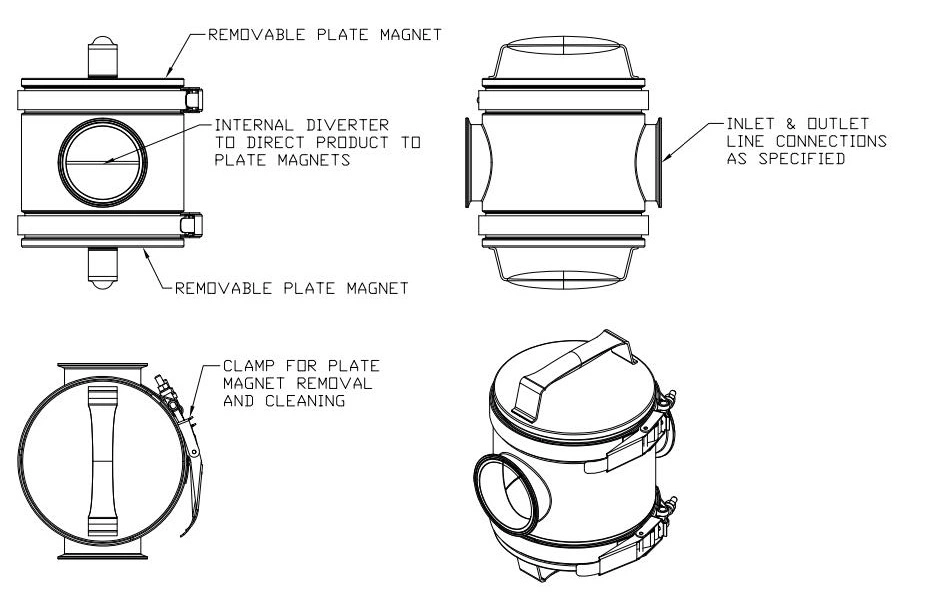

Ejet Trap Magnets are manufactured to remove micron sized ferrous metals from different kinds of liquids and slurry lines. The magnet assures a maximum exposure of contamination to the high intensity rods,without impeding the liquid flow.It can be used in a heated pipeline system, where temperature is critical to the viscosity of product.All units incorporate a sump type housing to trap non-ferrous particles. Liquid Traps may be installed horizontally, vertically, or on an angle without affecting their magnetic efficiency.Process line size, pressure and product viscosity are three key factors when considering this model magnetic separator.| Model | Application | diameterφ(mm) | Weight(kg) | A | B | C | H | N | M | φ1 | φ2 |

| LYSC-50 | Liquid | 50 | 19 | 115 | 85 | 250 | 270 | 8 | 14 | 125 | 150 |

| LYSC-65 | 65 | 27.3 | 120 | 105 | 360 | 380 | 8 | 14 | 165 | 192 | |

| LYSC-80 | 80 | 30.5 | 130 | 155 | 360 | 380 | 8 | 18 | 210 | 240 | |

| LYSC-100 | 100 | 45 | 130 | 180 | 380 | 405 | 8 | 18 | 240 | 270 | |

| LYSC-125 | 125 | 56.5 | 145 | 190 | 420 | 430 | 8 | 18 | 270 | 300 | |

| LYSC-150 | 150 | 72 | 180 | 190 | 450 | 465 | 8 | 18 | 300 | 330 | |

| LYSC-200 | 200 | 120 | 235 | 250 | 500 | 520 | 8 | 18 | 360 | 390 | |

| LYSC-250 | 250 | 19 | 265 | 280 | 530 | 640 | 12 | 18 | 395 | 425 | |

| LYSC-300 | 300 | 270 | 285 | 300 | 600 | 680 | 12 | 23 | 450 | 485 | |

| LYSC-350 | 350 | 350 | 325 | 340 | 680 | 750 | 12 | 23 | 500 | 540 | |

| LYSC-400 | 400 | 420 | 340 | 355 | 750 | 800 | 16 | 23 | 550 | 600 |

Standard Features:

- Plates at end of the tube protect the weldment from fracturing or breaking during handling, which ensures structural integrity and sanitary design

- Powerful Ceramic magnet material

- Stainless steel construction

- For use in product streams up to 75 psi (Capacities can vary, depending on tramp metal size, velocity and viscosity. 75 psi maximum line pressure recommended.)

- Quick-release clamps provide easy removal for inspection and cleaning of the magnetic element

- High energy Rare Earth magnet material

- Other line connection types available

- High pressure housing design

- Non-standard line sizes

Packing&shipping1. Packing: Export packing

2. Shipping time: 40 days after receive the deposit

Our service

Why Choose Fushun Ejet Magnetic Equipment With well-equipped professional engineers and strong technical force, Ejet have been in this feildfor 10 years, we cooperate with superior suppliers (Nord &Schneider)to keep our quality,the test ofmaterials is free if you are interested in our machine, strict quality checked for every machinebefore packing, engineers available to service machinery overseas, in addition, there is notonly after sales service support, but also technology support, "keep progress, persuitexcellence" would be keep forever.

Company infrormationFushun Ejet Magnetic Equipment is a manufacturer of Magntic Equipment with well-equipped professional engineers and strong technical force.

Our main products are eddy current separator, suspended magnetic separator,lifting magnets,etc.

With good quality, reasonable prices,our products are extensively used in solid waste treatment,metallurgical mine, power plants, coal mining and other industries. The products have beenexported to the United States, Canada, Japan and Australia.

We welcome new and old customers to contact us for future business relationships and mutualsuccess!

FAQ1. What is the MOQ of your machine?

A: Our MOQ is 1 set

2. How long is the machine warranty period?

A: the product warranty period is 12 months

In order to give you the responsible quotation, pls kindly inform us the following details:

1. What kind of material you are going to deal with?

2. What's the granularity of the material?

3. What's the producing capacity you are going to achieve?

Most suitable machine would be recomended to you according to your informations.

Contact Us:

Related Products

-

![Magnetic Metal Separating Machine Wet Permanent Drum Magnetic Separator]()

Magnetic Metal Separating Machine Wet Permanent Drum Magnetic Separator

-

![Sintered Rare Earth Neodymium Zinc Block-shaped Plate Magnet for Generator]()

Sintered Rare Earth Neodymium Zinc Block-shaped Plate Magnet for Generator

-

![SUS304 316L Stainless Steel Food Grade Magnetic Filter Clamp Connection Neodymium Magnetic Traps for Liquid Pipe Line]()

SUS304 316L Stainless Steel Food Grade Magnetic Filter Clamp Connection Neodymium Magnetic Traps for Liquid Pipe Line

-

![Housed Grids, Drawer Filter Magnets with Special Design]()

Housed Grids, Drawer Filter Magnets with Special Design