Rcdeb-12/14/16/18/20 Series Oil Forced Circulation Suspension Magnetic Iron Separator for Coal/Mining/Building Materials/Power Plant

Overview Package size per unit product 160.00cm * 580.00cm * 80.00cm Gross weight per unit product 3500.000kg Product De

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | RCDEB |

| Type | Magnetic Separator |

| Voltage | 380V |

| Weight | >10T |

| Material | Carbon Steel |

| Material Feature | Oxidation Resistant |

| Certification | ISO9001:2008, ISO9001:2000, CE |

| Energy Saving | Energy Saving |

| Warranty | 1 Year |

| Color | Customized |

| Customized | Customized |

| Condition | New |

| After-sales Service | Engineers Available Overseas |

| Certificate | Cmexc |

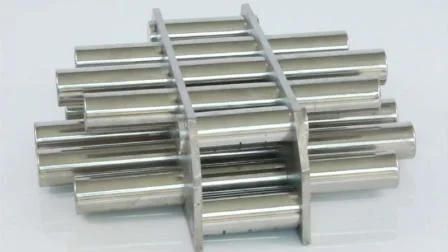

| Magnet Material | NdFeB Magnet |

| Belt Width | 1000/1200/1400/1600/1800/2000mm |

| Model | Rcdeb-10/12/14/16/18/20 |

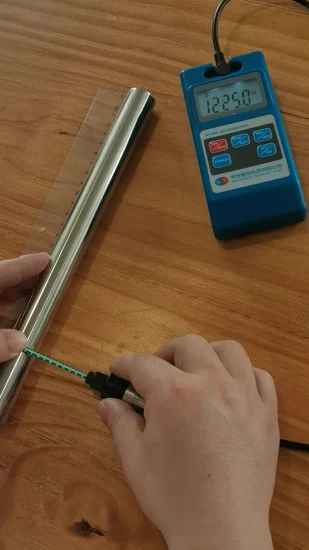

| Magnetic Intensity | 90-250mt |

| Belt Speed | Less Than 5.8m/S |

| Rating Height | 300-550mm |

| Min Quantity | 1PC |

| Advantage | Explosion Proof |

| Structure | Compact Structure Dust Proof |

| Magnet Filter | Neodymium |

| Usage | Coal,Power,Mining,Building Material etc. |

| Power | 8.5-125kw |

| Feature | Oil Forced Circulation |

| Coils | Anti Oxidation,Anti Rust |

| Transport Package | Steel Frame and Wooden Case |

| Specification | Customized |

| Trademark | Baite |

| Origin | China |

| HS Code | 8474100000 |

| Production Capacity | 500 PCS Per Year |

Packaging & Delivery

Package size per unit product 160.00cm * 580.00cm * 80.00cm Gross weight per unit product 3500.000kgProduct Description

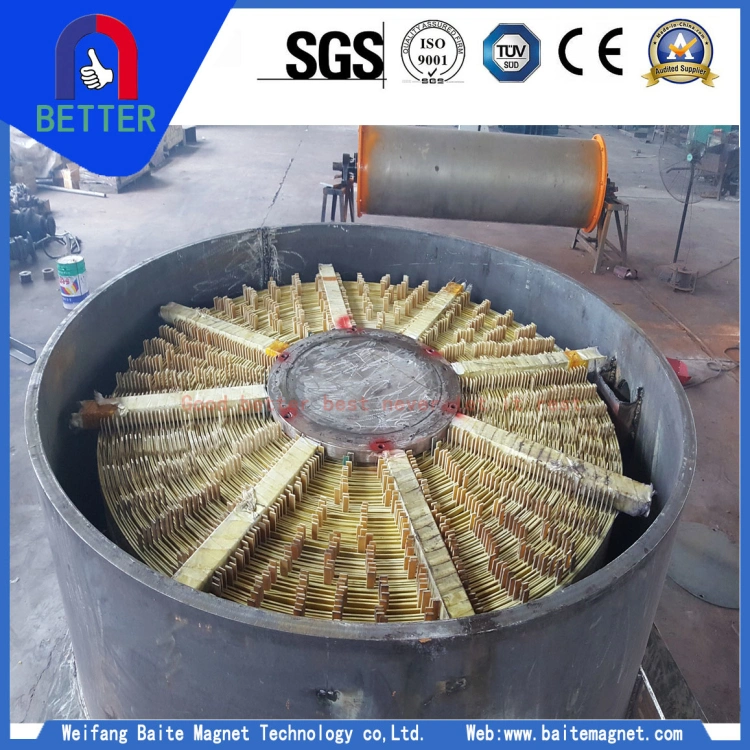

Introduction:For the port of coal transportation, big thermal power plant, mine and building material. It can also work in the harsh environment such as dust, humidity, salt fog.Features:-- High-quality cooling oil and optimized oil circulating design.-- No noise, quick heat releasing, low temperature rising.-- Compact structure, easy maintenance, reliable and longtime trouble-free operation.-- The coils have unique features like anti-oxidation, anti-rust and good insulation. Technology Characteristics:-- Absorbing the advanced oil forced circulation technology for the large or medium transformer both home and abroad, it features with low temperature (≤40°C) rising and the technology is reliable and safety.-- Magnetic route is short, magnetic waste is less, the gradient is high and removing iron efficiently.-- Light weight reasonable oil line, compact cooling structure and high heat-releasing efficiently.-- The exciting coil is completely dipped into the transformer oil to be dust-proof, moisture-proof and anti-corrosion.-- Made three-dimensional excitation coil winding, the area for heat releasing is large to control the temperature (≤40°C) for long service life.

| NO. | Model | conveyor belt width (mm) | Suspension height(h=mm) | Magnetic intensity(≥mt) | Belt speed(m/s) | Existing power (≤kw) | Condenser power (≤kw) | Weight(kg) | Appearance size (mm) | |

| 1 | RCDEB-10 | T1 | 1000 | 300 | 90 | ≤5.8 | 6.5 | 0.25 | 2600 | 1700×1210 |

| T2 | 120 | 9.5 | 0.25 | 2950 | 1700×1250 | |||||

| T3 | 150 | 15.0 | 0.25 | 3470 | 1750×1280 | |||||

| 2 | RCDEB-12 | T1 | 1200 | 350 | 90 | 9.0 | 0.25 | 2900 | 1750×1280 | |

| T2 | 120 | 14.0 | 0.25 | 3500 | 1750×1280 | |||||

| T3 | 150 | 20.0 | 0.25 | 5400 | 2000×1380 | |||||

| 3 | RCDEB-14 | T1 | 1400 | 400 | 90 | 14.0 | 0.25 | 3000 | 1750×1280 | |

| T2 | 120 | 20.0 | 0.25 | 5500 | 2000×1420 | |||||

| T3 | 150 | 29.0 | 0.25 | 7460 | 2230×1450 | |||||

| 4 | RCDEB-16 | T1 | 1600 | 450 | 90 | 18.0 | 0.25 | 5400 | 2000×1420 | |

| T2 | 120 | 28.0 | 0.25 | 7500 | 2230×1450 | |||||

| T3 | 150 | 32.0 | 0.25 | 8550 | 2350×1480 | |||||

| T4 | 175 | 52.0 | 0.75 | 10200 | 2570×1550 | |||||

| T5 | 200 | 70.0 | 0.75 | 11875 | 2570×1600 | |||||

| T6 | 225 | 85.0 | 1.1 | 14250 | 2570×1650 | |||||

| T7 | 250 | 104.0 | 0.55×2 | 15500 | 2570×1720 | |||||

| 5 | RCDEB-18 | T1 | 1800 | 500 | 90 | 26.0 | 0.75 | 7600 | 2250×1480 | |

| T2 | 120 | 32.0 | 0.75 | 8600 | 2350×1480 | |||||

| T3 | 150 | 40.0 | 0.75 | 10500 | 2460×1500 | |||||

| T4 | 175 | 56.0 | 0.75 | 14600 | 2600×1600 | |||||

| T5 | 200 | 75.0 | 0.75 | 17600 | 2650×1650 | |||||

| T6 | 225 | 90.0 | 1.1 | 18500 | 2700×1700 | |||||

| T7 | 250 | 107.0 | 0.55×2 | 19200 | 2750×1720 | |||||

| 6 | RCDEB-20 | T1 | 2000 | 550 | 90 | 30.0 | 0.75 | 8800 | 2400×1480 | |

| T2 | 120 | 39.0 | 0.75 | 10600 | 2500×1500 | |||||

| T3 | 150 | 41.0 | 0.75 | 12500 | 2660×1500 | |||||

| T4 | 175 | 70.0 | 0.55×2 | 21600 | 2750×1620 | |||||

| T5 | 200 | 83.0 | 0.55×2 | 22500 | 2820×1650 | |||||

| T6 | 225 | 104.0 | 0.55×2 | 23900 | 2870×1680 | |||||

| T7 | 250 | 125.0 | 0.55×2 | 25600 | 2900×1750 | |||||

Dimension drawing:

CertificationsPackaging & Shipping

Weifang Baite Magnet Technology is a modern enterprise, which was founded by Weifang Hengli Magnet Equipment Factory and Weifang Kexin magnet equipment factory in conjunction with other domestic investors. It is the enterprise of producing magnetic and powder equipment, is the larger magnetic equipment manufacturer of research and development, engineering design, production and installation, commissioning and service.The company mainly produces over 30 series 200 kinds of specifications, such as magnetic separator, de-ironing separator, crusher, disk-type, permanent magnet vacuum filter, metal detector, grinding equipment, aggregate equipment, grinding and processing equipment. The service is related to more than 10 areas, such as electricity, coal, building materials, metallurgy, ports, mining, nonferrous metals, powder environmental protection. At present, we have provided more than 7000 domestic and foreign customers with reliable and value-added and convenient professional equipment and programs, and at the same time, Products are exported to Russia, Mongolia, India, Indonesia, Malaysia, the Philippines, Vietnam, Thailand, Iran, the United Arab Emirates, Pakistan, Kazakhstan, South Africa, Zimbabwe, Brazil, Chile, Peru, Australia and other dozens of countries and regions.There is no best, only better. Baite has firmly implemented ISO9001: 2000 international quality management system standard and ISO10012 international quality inspection system standard, relying on technological innovation, and continuously improve core competitiveness. We innovate and constantly improve product performance, quality, extend the application scope to meet user higher demand. To become an international leader in magnetic application system is the goal of Baite...With well-equipped professional engineers and strong technical force, Baite has been in this feild for 10 years, we cooperate with superior suppliers to keep our quality, the test of materials is free if you are interested in our machine, strict quality checked for every machine before packing, engineers available to service machinery overseas, inaddition, there is not only after sales service support, but also technology supportBaite company commitments the aim of " striving for survival with top quality, promoting development with good reputation, winning the world with good faith ". We warmly welcome all the friends to the cooperation!

Exhibition in Indonesia:

laboratory

Our other main products:

1.Pre-sale services: enthusiasmWe provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.2.one-year warranty to make sure your machine runs consistently.We always offering lifelong services and provide spare parts for a long term,and repair main parts under right using for free in two years.3.Technical services3.1 Design of production line and solutions according to buyer's requirement.3.2 In 7 days after the receipt of deposit, the seller shall provide related technical documents for equipment installation, in addition to those with special requirements.3.3 Before delivery, the seller can modify the previous solutions according to buyer's requirement. 4.After-sales service4.1 During the installation and commissioning, the seller shall send technician to the site for instruction of installation and commissioning, and for training of workers.4.2 If there is any equipment failure caused by the buyer, the seller shall assist the maintenance of machines and replacement of fittings, and charges appropriate fees.4.3 Beyond the guarantee period, the seller can provide services and fittings at a most preferential price. 4.4The seller can provide consultation and inspection services freely for other products, especially for the up-stream and down-stream products of our equipment.

FAQQ: Are you a factory ?

A:Yes,we are factory, which was established in 2003.We focus on providing expert service including design, manufacture, installation & maintenance

Q: Terms of Payment:A:30% of the total amount by TT as deposit, the balance to be paid by TT or L/C at sight before the machines leaving seller' factory.100% irrevocable L/C at sight.

Q:Time for preparation of goods:A:The above machines shall be ready for delivery during 25 days from the date of receiving the deposit/LC, excluding the time of waiting for shipment. Q:Guarantee period: A:The guarantee period for the above machines is twelve months from the date of putting into use, but not exceeds twenty-four months after the machines leaving seller's factory. It is not applicable for quick wear parts

Q: May I know the status of my order?

A: Yes. We will send you information and photos at different production stage of your order. Every step will be send to you in time

Q: Can I customize shelving or racking at my own size? A: Sure

Q: If i need the complete mineral processing line. is Baite able to help us build it?

A: Yes, we can help you combine a complete mineral processing line. and give you related professional advice as long as you need.There is a rich experience engineer team of us. we had already build many mining projects in China & Overseas. You can believe our quality and service.

Information for RFQ:

1. Which kind of material are you going to deal with?

2. What is the width of the conveyor belt?

3. What is the processing capacity you are going to achieve?

Welcome Inquiry & we will reply to you within 24 hours.

Related Products