Customized Black Epoxy Resin NdFeB Barrel-Plated Epoxy Magnetic Steel Magnetic Material

1.Operating temperature When the magnet exceeds the specified working temperature, it will cause the magnet to demagneti

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | CA-04-2 |

| Production Capacity | 5000 |

Product Description

Applications | Automotive, Medical, Consumer Electronics, Military, Aerospace and etc. |

Processing Service | Material Burdening, Melting, Forging, Hot Rolling, Cold Rolling, Slitting, Cold drawing, Cutting off, Rough machining, Heat treatment, 100% magnetic inspection, Fine machining, Final inspection/packaging |

Size | Customized |

Shape | Block, Rod, Disc, Ring, Arc, Customized |

Grade | FeCrCo10/3, FeCrCo12/4, FeCrCo16/2, FeCrCo28/5, FeCrCo30/4, FeCrCo35/5, FeCrCo36/5, FeCrCo44/4, FeCrCo52/5 |

Tolerance | ±1%, Customized |

Magnetism Direction | Length, Width, Thickness, Axial, Diameter, Radial Multi-poles, Customized |

Coating | Nickle, Zinc, Epoxy, Parylene, Gold, Ag, Al, PTFE, Everlube and etc. |

Density | 7.5-7.6g/cm³ |

1.Operating temperature

When the magnet exceeds the specified working temperature, it will cause the magnet to demagnetize or demagnetize. Please use it carefully.

2.Magnetizing direction

The magnet starts from the production of slices, which determines the magnetization direction and working surface of the product, which cannot be changed.

3.Operation Tips

Installation and use: magnets are not iron (iron is cast, like iron wire, with good toughness and continuous falling; magnets are made of powder fired, like ceramic properties, hard but brittle, no toughness, and will break when touched or dropped on the ground), The magnet is made of rare earth alloy crystalline material, which is hard and brittle, and is fragile. After magnetization, it is naturally attracted to each other without external force control, and it is easy to collide and break. Please pay attention to correct installation and use. Sturdy use, please do not use electric work, it is easy to squeeze and cause the magnet to break.

Related Products

-

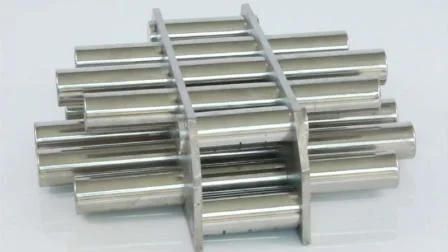

![Magnetic Filter/ Grill/Rod/ Grate Stirrer Bar Magnet Neodymium Permanent Magnetic Grid]()

Magnetic Filter/ Grill/Rod/ Grate Stirrer Bar Magnet Neodymium Permanent Magnetic Grid

-

![Super Powerful Permanent Neodymium Magnet NdFeB Magnetic Filter Magnetic Grill 12000GS]()

Super Powerful Permanent Neodymium Magnet NdFeB Magnetic Filter Magnetic Grill 12000GS

-

![Magnetic Liquid Filter Food Industry Easy Cleaning Neodymium Liquid Magnetic Trap]()

Magnetic Liquid Filter Food Industry Easy Cleaning Neodymium Liquid Magnetic Trap

-

![New Design Magnet Drawer Separator, Customized Magnetic Drawer]()

New Design Magnet Drawer Separator, Customized Magnetic Drawer