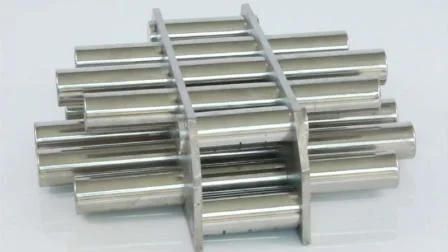

Customized Powerful Magnetic Shelf Magnetic Grill

Customized Powerful Magnetic Shelf Magnetic Grill Nanjing Huajin Magnetic Materials Co., Ltd. Specializing in the produc

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | MF25 |

| Application | Industrial Magnet, Hopper Magnet |

| Shape | Bar Filter |

| Coating | SUS304/316L |

| Grade | N35-N52, 38m-48m, 35h-48h, 33sh-44sh, 30uh-35uh |

| Type | Permanent&Strong |

| Composition | Rare Earth NdFeB Magnet |

| Product | Magnetic Filter |

| Gauss | 6000 to 14000 GS |

| Size | Customized Size Available |

| Layer | Single or Double |

| Working Temp. | Max 392f |

| Lead Time | 5-7 Days |

| Transport Package | Box or Carton |

| Specification | RoHS SGS MSDS |

| Trademark | HJ |

| Origin | Nanjing, Jiangsu |

| HS Code | 85051110 |

| Production Capacity | 5000000sets/Year |

Product Description

Customized Powerful Magnetic Shelf Magnetic Grill| Item | Neodymium Magnetic Rod |

| Brand name | Huajin Magnet |

| Usage | Industry, food industry, Plastics Industry ect. |

| Material | Neodymium-iron-boron |

| Process | Sintering-Machining-Coating-Magnetizing-Packing |

| Size | Customized |

| Tpye | Permanent&strong |

| M.O.Q | 1PC |

| Tube | SUS304/316L |

| Gauss | 6000-12000GS |

| Packing | carton & wooden & pallet & by customer requirements. |

| Delivery time | 3-7 days after order confirmation |

| Payment term | T/T, L/C, PayPal, Western Union |

| Trade term | EXW, FOB, F&C, FCR, CIF ect. |

| Certifications | ISO9001,SGS |

| Main products | Round/block/ring magnet, PVC magnetic button, magnet filter, magnetic rod/bar/stick |

Nanjing Huajin Magnetic Materials Specializing in the production and saleof magnetic NdFeB, magnetic bar, magnetic products, magnetic frame. Magnets ofvarious shapes and sizes can be produced according to customer requirements, suchas packaging diskette, the motor magnetic tile, magnetic ring, toy bar magnet, magneticball, with the exception of iron magnetic rods, magnetic hooks, magnetic separator box;Surface treatment: Gold, silver, plated epoxy, nickel-plated copper-nickel, zinc,chromium, titanium (blue zinc, black zinc, color zinc), above the surface treatment tomeet environmental requirements.

| Grade | Remanence | Coercivity Force | Intrinsic Coercive Force | Max. Energy Product | Working Temp. | ||||

| Br | Hcb | Hcj | (BH)max | ||||||

| mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥ 868 | ≥ 10.9 | ≥ 955 | ≥ 12 | 263-287 | 33-36 | 80 ° C |

| N38 | 1220-1250 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 955 | ≥ 12 | 287-310 | 36-39 | 80 ° C |

| N40 | 1250-1280 | 12.5-12.8 | ≥ 907 | ≥ 11.4 | ≥ 955 | ≥ 12 | 302-326 | 38-41 | 80 ° C |

| N42 | 1280-1320 | 12.8-13.2 | ≥ 915 | ≥ 11.5 | ≥ 955 | ≥ 12 | 318-342 | 40-43 | 80 ° C |

| N45 | 1320-1380 | 13.2-13.8 | ≥ 923 | ≥ 11.6 | ≥ 955 | ≥ 12 | 342-366 | 43-46 | 80 ° C |

| N48 | 1380-1420 | 13.8-14.2 | ≥ 923 | ≥ 11.6 | ≥ 876 | ≥ 12 | 366-390 | 46-49 | 80 ° C |

| N50 | 1400-1450 | 14.0-14.5 | ≥ 796 | ≥ 10.0 | ≥ 876 | ≥ 11 | 382-406 | 48-51 | 60 ° C |

| N52 | 1430-1480 | 14.3-14.8 | ≥ 796 | ≥ 10.0 | ≥ 876 | ≥ 11 | 398-422 | 50-53 | 60 ° C |

| 35M | 1170-1220 | 11.7-12.2 | ≥ 868 | ≥ 10.9 | ≥ 1114 | ≥ 14 | 263-287 | 33-36 | 100 ° C |

| 38M | 1220-1250 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 1114 | ≥ 14 | 287-310 | 36-39 | 100 ° C |

| 40M | 1250-1280 | 12.5-12.8 | ≥ 923 | ≥ 11.6 | ≥ 1114 | ≥ 14 | 302-326 | 38-41 | 100 ° C |

| 42M | 1280-1320 | 12.8-13.2 | ≥ 955 | ≥ 12.0 | ≥ 1114 | ≥ 14 | 318-342 | 40-43 | 100 ° C |

| 45M | 1320-1380 | 13.2-13.8 | ≥ 995 | ≥ 12.5 | ≥ 1114 | ≥ 14 | 342-366 | 43-46 | 100 ° C |

| 48M | 1360-1430 | 13.6-14.3 | ≥ 1027 | ≥ 12.9 | ≥ 1114 | ≥ 14 | 366-390 | 46-49 | 100 ° C |

| 50M | 1400-1450 | 14.0-14.5 | ≥ 1033 | ≥ 13.0 | ≥ 1114 | ≥ 14 | 382-406 | 48-51 | 100 ° C |

| 35H | 1170-1220 | 11.7-12.2 | ≥ 868 | ≥ 10.9 | ≥ 1353 | ≥ 17 | 263-287 | 33-36 | 120 ° C |

| 38H | 1220-1250 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 1353 | ≥ 17 | 287-310 | 36-39 | 120 ° C |

| 40H | 1250-1280 | 12.5-12.8 | ≥ 923 | ≥ 11.6 | ≥ 1353 | ≥ 17 | 302-326 | 38-41 | 120 ° C |

| 42H | 1280-1320 | 12.8-13.2 | ≥ 955 | ≥ 12.0 | ≥ 1353 | ≥ 17 | 318-342 | 40-43 | 120 ° C |

| 45H | 1300-1360 | 13-13.6 | ≥ 963 | ≥ 12.1 | ≥ 1353 | ≥ 17 | 326-358 | 43-46 | 120 ° C |

| 48H | 1370-1430 | 13.7-14.3 | ≥ 995 | ≥ 12.5 | ≥ 1353 | ≥ 17 | 366-390 | 46-49 | 120 ° C |

| 33SH | 1130-1170 | 11.3-11.7 | ≥ 844 | ≥ 10.6 | ≥ 1592 | ≥ 20 | 247-271 | 31-34 | 150 ° C |

| 35SH | 1170-1220 | 11.7-12.2 | ≥ 876 | ≥ 11.0 | ≥ 1592 | ≥ 20 | 263-287 | 33-36 | 150 ° C |

| 38SH | 1220-1250 | 12.2-12.5 | ≥ 907 | ≥ 11.4 | ≥ 1592 | ≥ 20 | 287-310 | 36-39 | 150 ° C |

| 40SH | 1240-1280 | 12.5-12.8 | ≥ 939 | ≥ 11.8 | ≥ 1592 | ≥ 20 | 302-326 | 38-41 | 150 ° C |

| 42SH | 1280-1320 | 12.8-13.2 | ≥ 987 | ≥ 12.4 | ≥ 1592 | ≥ 20 | 318-342 | 40-43 | 150 ° C |

| 45SH | 1320-1380 | 13.2-13.8 | ≥ 1003 | ≥ 12.6 | ≥ 1592 | ≥ 20 | 342-366 | 43-46 | 150 ° C |

| 30UH | 1080-1130 | 10.8-11.3 | ≥ 812 | ≥ 10.2 | ≥ 1990 | ≥ 25 | 223-247 | 28-31 | 180 ° C |

| 33UH | 1130-1170 | 11.3-11.7 | ≥ 852 | ≥ 10.7 | ≥ 1990 | ≥ 25 | 247-271 | 31-34 | 180 ° C |

| 35UH | 1180-1220 | 11.8-12.2 | ≥ 860 | ≥ 10.8 | ≥ 1990 | ≥ 25 | 263-287 | 33-36 | 180 ° C |

| 38UH | 1220-1250 | 12.2-12.5 | ≥ 876 | ≥ 11.0 | ≥ 1990 | ≥ 25 | 287-310 | 36-39 | 180 ° C |

| 40UH | 1240-1280 | 12.5-12.8 | ≥ 899 | ≥ 11.3 | ≥ 1990 | ≥ 25 | 302-326 | 38-41 | 180 ° C |

Widely Applications of neodymium magnets:

1) Servomotor, step motor, DC motor and linear motor2) Loudspeaker, headphone, earphone and microphones3) Medical Industry: Medical equipment, Magnetic therapy products4) Holding system equipment5) Food Industry: Filter Iron impurities from food products.6) Kitchenware

Our Team Work Plan:1.Continuously effort to get some new technicial to meet customers requirements.2. Reply your query within 12 hours3. 3 days for magnet sample made4. Timely Lead time in 3-10 days5. Quality control from material prepared to products finished. And apply the productstest report.6. Any query we would follow up after sales.

Payment Term:T/T, L/C, Western Union, PayPal.Package & Shipment1. By Express(DHL, FedEx, TNT, UPS ect): Door to door, Short Delivery time, 3-5 days.2. By Air: Short Delivery Time, 3-7 days.3. By Sea: Cheap Shipping Cost, 7-30 days.Package: Magnetic Isolation PackageCarton: 36*27*15CMFAQ:1. How to get quick quotation?Kindly offer us the specific size, quantity, coating(zinc/nickel), magnetism direction ectother requiries. Then best price will be offered ASAP. 2.What about the lead time?(1) Sample: 5-7 days. (2) Batch quantity: 7-12 days.3.What's the MOQ?Normally regular Size: ≥1 Piece.4. Terms of Paymemt:(1). T/T in advance(telegraphic transfer-bank order)(2). Western Union cash - for small order or samples order.(3). PayPal- for small order, quick receiptPlease feel free to contact me for any questions and requiries.

Related Products

-

![Rcdd Series Self Cleaning Over Belt Electric Magnetic Iron Separator in Coal Handling/Mining/Cement/Chemical/Power Plant]()

Rcdd Series Self Cleaning Over Belt Electric Magnetic Iron Separator in Coal Handling/Mining/Cement/Chemical/Power Plant

-

![Industrial Plate Magnet Cube Neodym Magnet Magnetic Rods Magnet]()

Industrial Plate Magnet Cube Neodym Magnet Magnetic Rods Magnet

-

![Hopper Neodymium Material Magnet Clamp Flange Grate Bar Rod Grid Separator Oil Food Industrial 304 316 Filter Liquid Magnetic Trap]()

Hopper Neodymium Material Magnet Clamp Flange Grate Bar Rod Grid Separator Oil Food Industrial 304 316 Filter Liquid Magnetic Trap

-

![Exterior Arch Grill Design for Aluminum Half Moon Casement Window and Door]()

Exterior Arch Grill Design for Aluminum Half Moon Casement Window and Door