Sdm Factory Directed High Temperature Resistance AlNiCo Rotor Magnet

Alnico Rotor Magnet, Multi-Poles Rotor Magnet Permanent AlNiCo Six-Poles, AlNiCo Rotor Magnet 6-Poles for Synchronous Mo

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | SDMARM |

| Other Coating | Ni, Ni-Cu-Ni, Zn(Cr3+), Tin, Epoxy, Ni-AG, Ni-Au |

| Tolerance | +/-0.05 |

| Delivery Detail | 10~20 Days After Order Confirmed |

| Export Markets | Global |

| OEM Service | Yes |

| Transport Package | Sea Pallet / Air Carton / Express Packaging |

| Specification | RoHS |

| Trademark | SDM |

| Origin | China (Mainland) |

| HS Code | 8505111000 |

| Production Capacity | 100, 000 PCS/Month |

Product Description

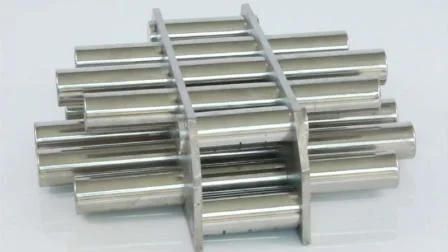

Alnico Rotor Magnet, Multi-Poles Rotor Magnet Permanent AlNiCo Six-Poles, AlNiCo Rotor Magnet 6-Poles for Synchronous Motor, Cast Alnico Motor Rotor Magnet System, Multi-Poles AlNiCo Magnets for Rotor, Al-Ni-Co rotor shaft magnet, Permanent alnico 5 rotor magnet, Six Multi Polar Alnico Magnetic Rotor Core, custom alnico rotor magnet China Supplier

Multi-Poles Rotor Magnet Permanent AlNiCo Six-Poles Paramenters

Size: 1.870″ Dia. x 1.250″

Number of Poles: 6

Features:

Permanent alnico magnet material

Especially effective on thin metal

6-Pole Magnetic face

Counter sunk center mounting Hole.

Alnico rotor magnets are designed with multiple poles; each pole alternates in polarity. The hole in the rotor is designed for mounting onto shafts. They are excellent for use in synchronous motors, dynamos and air turbine generators.

Features

• Alnico rotor magnets are made with Alnico 5 material and have a maximum temperature of approximately 1000°F.

• They are supplied un-magnetized unless otherwise requested. Magnetization after assembly is required to gain the full benefits of these magnets.

• SDM provide a magnetization service for assemblies incorporating these magnets. We can normally magnetize them within one working day of receipt.

SDM can supply various sizes of AlNiCo magnets, according to per customer's requests and designs. Please contact us and offer the shape, size, tolerance and grade of ALNiCO rotor magnets. If you need assistance with your requirements, please contact us.

With the best temperature resistance and the most advanced commercial magnet material, Alnico providing for excellent stability over a wide temperature range. A properly designed circuit using alnico magnets will have a stable flux output during temperature fluctuations. Although Alnico displays considerable residual induction it conversely exhibits among the lowest coercivity of any magnetic material. A consequence of low coercivity is sensitivity to demagnetizing effects caused by external magnetic fields, shock, and application temperatures. For critical applications, Alnico magnets can be magnetically stabilized to minimize these effects. Alnico magnets can be partially demagnetized if like poles of magnets are brought together. Placing individual magnets in contact with ferrous materials can also partially demagnetize them. Care must be taken in handling magnetized magnets.

Related Products

-

![Wholesale Grey Color Balcony Aluminum Grill Design for Sliding Window]()

Wholesale Grey Color Balcony Aluminum Grill Design for Sliding Window

-

![Rcyd-Z12 Removing Iron Magnetic Separator Equipment]()

Rcyd-Z12 Removing Iron Magnetic Separator Equipment

-

![Series Ctg Iron Ore Dry Type Permanent Magnetic Roller/Drum Separator for Sand]()

Series Ctg Iron Ore Dry Type Permanent Magnetic Roller/Drum Separator for Sand

-

![Wholesaler Neodymium Waterproof Iron Industry Permanent Rare Earth Neodymium Arc Tile Magnet Magnet Magnetic Materials]()

Wholesaler Neodymium Waterproof Iron Industry Permanent Rare Earth Neodymium Arc Tile Magnet Magnet Magnetic Materials