Manganese Iron Ore Processing Plant Drum Magnetic Separator Machine for Sale

Overview Package size per unit product 260.00cm * 100.00cm * 150.00cm Gross weight per unit product 12000.000kg Manganes

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | CTB series |

| Material | Carbon Steel |

| Material Feature | Heat Resistant |

| Certification | ISO9001:2008, ISO9001:2000, CE |

| Energy Saving | Energy Saving |

| Warranty | 1 Year |

| Color | Multi Color |

| Customized | Customized |

| Condition | New |

| After-sales Service | Long Service Life |

| Applicable Industries | Manufacturing Plant, Construction Works , Energy & |

| Machinery Test Report | Provided |

| Video Outgoing-Inspection | Provided |

| Core Components | Magnet System |

| Key Selling Points | Low Noise Level |

| Magnetic Field Intensity | 1500OE |

| Installation | Under Guidance |

| Subcategory | Mining Machinery |

| Category | Recycling & Disposal in China |

| Factory Visit | Welcome |

| Magnetic Intensity on The Drum Surface | Customized or Make as Per The Specific Mineral |

| Application | Preseparate The Lean/Low-Grade Ore with Only 5-20% |

| Feed-in Size | 0-16mm |

| Drum Rotary Speed | 0 - 50 R/Min |

| Transport Package | Standard Container |

| Specification | According to model |

| Trademark | Baichy |

| Origin | Zhengzhou, China |

| HS Code | 8474100000 |

| Production Capacity | 30 Set / Month, 90% Recovery Rate |

Packaging & Delivery

Package size per unit product 260.00cm * 100.00cm * 150.00cm Gross weight per unit product 12000.000kgProduct Description

Manganese Iron Ore processing plant Drum Magnetic Separator Machine for SaleProduct Description

Permanent drum magnetic separator is a magnetic separation equipment for various metallurgical mines to separate magnetic fine particles or remove magnetic minerals mixed in non-magnetic minerals. Wet magnetic separator is a commonly used magnetic separation equipment in iron ore processing plants, which requires water as a medium, it can sort fine particles of ore. Magnetic separator is mainly used for magnetite, limonite, ilmenite, etc. It can separate elemental minerals from gangue, sediment to improve the quality of minerals.

<<< Magnetic separator features >>>

<<< Magnetic separator working principle >>>Slurry enters chute through ore tank, and then gets into separating zone by waterpower. Minerals with strong magnetism is absorbed on the barrel's surface under the force of magnetic field and get into the ore concentrate outlet along with the rotation of cylinder. After leaving the magnetic field, they flow into ore concentrate box by the action of gravity and flushing water. Gangue and ore with weak magnetism are discharged into a pipe in the opposite direction of cylinder rotation.

Product Parameters

| Model | Magnetic field intensity (oe) | Capacity (t/h) | Power (kw) |

| CTB600X900 | 1450 | 8-15 | 1.1 |

| CTB600X1800 | 1500 | 15-25 | 2.2 |

| CTB750X1800 | 1550 | 30-45 | 3 |

| CTB900X1800 | 1650 | 35-60 | 4 |

| CTB1050X2400 | 1650 | 60-95 | 5.5 |

| CTB1200X3000 | 1650 | 80-150 | 7.5 |

| CTB1500X3000 | 1650 | 120-200 | 11 |

Detailed Photos

Baichy Heavy Industrial Machinery is a hi-tech, engineering group. We are specialized in the research, development, and production of stone crushing, powder grinding, mineral processing equipments and other related devices. Our products have been sold to 120 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.Baichy FactoryHeadquarter of Baichy is located in Zhengzhou city, China and now we have two manufacturing bases as our strong support. One is located in Jiaozuo about 200,000 square meters, and the other is in Xingyang city, about 100,000 square meters.There are more than 200 sets of various large and medium-sized metal processing lathe, riveting machine, welding equipment and assembly equipment.

After Sales Service

Pre-sale services: (1) Advice of model choice.(2) Design and manufacture machines according to customer's special requirements(3) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design thebest processes and program After-sale services :(1) Arrange technicians to go to the site to guide installation(2) If your machine is out of warranty period, Baichy could provide the spare parts.(3) Complete sets of equipment installed, Baichy could arrange technical staff on-site for install, dubug and training until the user' satisfaction.

Related Products

-

![Neodymium Magnet Ring Shape N38 Grade Nickel Coating NdFeB Magnetic Materials]()

Neodymium Magnet Ring Shape N38 Grade Nickel Coating NdFeB Magnetic Materials

-

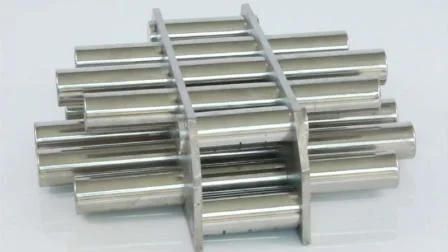

![Magnet Hopper Food Grate Liquid Line Magnetic Trap for Chemical Industry]()

Magnet Hopper Food Grate Liquid Line Magnetic Trap for Chemical Industry

-

![Strong Permanent NdFeB Magnetic Rod]()

Strong Permanent NdFeB Magnetic Rod

-

![Rcdeb-12/14/16/18/20 Series Oil Forced Circulation Suspension Magnetic Iron Separator for Coal/Mining/Building Materials/Power Plant]()

Rcdeb-12/14/16/18/20 Series Oil Forced Circulation Suspension Magnetic Iron Separator for Coal/Mining/Building Materials/Power Plant